ProteoSense RapidScan Device Aims to End Foodborne Illness

What if we could eliminate foodborne illness?

That’s the potential of ProteoSense, a Columbus-based startup that is developing a portable diagnostic device for food safety testing.

Reducing pathogen testing time from days to 15 minutes or less

Using RapidScan, ProteoSense’s handheld testing device, growers, processors, shippers, and wholesalers can test food and environmental samples for potentially dangerous pathogens without having to send samples to a lab and wait three or four days for results.

Using RapidScan, ProteoSense’s handheld testing device, growers, processors, shippers, and wholesalers can test food and environmental samples for potentially dangerous pathogens without having to send samples to a lab and wait three or four days for results.

Customers purchase a meter and a plug-in, single-use sensor cartridge for the bacteria they want to detect. Customers turn on the device, apply a liquid sample and the results are ready in minutes with high accuracy and without time-consuming sample incubation.

“We have recently completed experiments that prove that we can detect live salmonella and differentiate that from dead salmonella with no sample incubation,” said Mark Byrne, ProteoSense CEO. “We are gearing up to do another set of experiments, financed by a strategic partner in the food industry.”

ProteoSense has a dozen plus major produce growers and processors who want to be part of a beta test. “We’ll buy it when you have it, they’ve told us,” said Byrne, who has led startups for 13 years. “The market is bigger than we originally thought,” Byrne said. “This is a multi-billion dollar opportunity with a major unmet need.”

A perfect storm for striking down foodborne pathogens

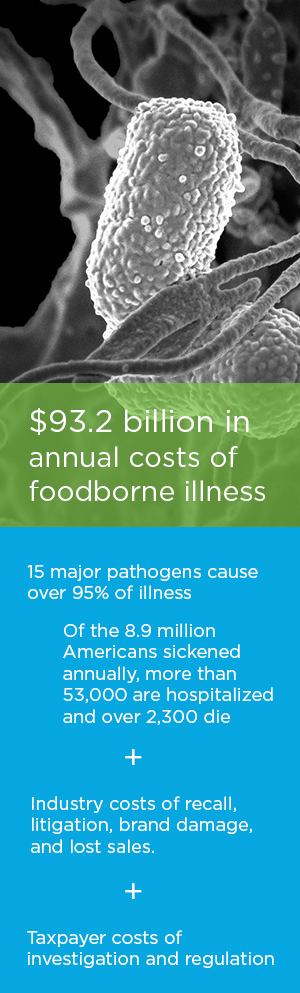

There is a high awareness, and potentially a higher incidence, of foodborne illness today. Food companies have supply chains that cross borders and stretch around the world. The US Food Safety Modernization Act of 2011 requires certain preventive measures that increase the number and frequency of tests.

Major players in the food industry, such as Costco, and YUM Brands, are requiring more rigorous examination of the food supply, including pre-harvest testing.

Major players in the food industry, such as Costco, and YUM Brands, are requiring more rigorous examination of the food supply, including pre-harvest testing.

“Multiple factors are increasing awareness and action at all levels,” Byrne said. “It is the perfect storm for what we are selling—timely and accurate information at the point of need.”

With a customer base concentrated in four regions of the country, ProteoSense doesn’t require an extensive national sales force.

“The receptivity of the customers and how strong the need is and the strength of the market has been surprising,” Byrne said. “The market dynamics are much more favorable than a year ago.”

And that’s not all that’s favorable.

“The strength, persistence, and resiliency of this team has been great,” Byrne said. “We have a very committed and engaged group of professionals who have completely bought into this opportunity—not just the people in the company, but the Board and our external advisors as well.”

The Backyard Effect

Byrne is working to forge strategic partnerships with Ohio companies, trade associations, and with major entities in Ohio’s entrepreneurial ecosystem.

“Ohio is a big agricultural state,” he said. “We’ve made lots of contacts and talked with major trade organizations and key customers in Ohio.”

ProteoSense is finding the talent the company needs. “Marketing, selling, design—all are available here,” said Byrne.

The business model for a company that produces devices, even if most of the manufacturing is contracted out, calls for more capital investment earlier than software or IT deals.

ProteoSense was a 2014 recipient of investment from the Technology Concept Fund, which includes capital committed by The Ohio State University and Ohio Third Frontier, and managed by Rev1.

ProteoSense was also chosen after a highly competitive review process to receive a $100,000 grant from the Ohio Third Frontier Technology Validation & Start-up Fund. Byrne also invested in the company.

“We also are benefiting,” Byrne said, “from a strong network of people in this state who know how to get things done, and from being located at Rev1 with the laboratory space we need.”